Naše automatske mašine za punjenje i zatvaranje sa rotacijskim kotačima pogodne su za punjenje proizvoda tankih do srednje debelih proizvoda, kao što su tečni lekovi, tonik, perm losion, osveživač vazduha, nega kože itd. Sadrže ih kompaktna konfiguracija, zauzeta je mala površina, lijep izgled, lako prilagođavanje i široka primjenjivost, zbog čega se mogu široko koristiti u farmaceutskoj, pesticidnoj, svakodnevnoj kemijskoj, prehrambenoj ili drugoj industriji.

U ovim serijama akcije punjenja i zatvaranja pokreću se preciznim mehaničkim prijenosom, što može učinkovito garantovati kvalitetu proizvoda. Sve radne stanice, uključujući punjenje, punjenje poklopca, zatvaranje opremljene su oko jednog zvjezdanog kotača, čime se i radni prostor i potrebni rukovaoci mogu uvelike smanjiti. Automatski i neprekinuti način proizvodnje može vam pomoći da garantirate potreban volumen proizvodnje. Biramo dobar materijal i dijelove za sastavljanje naših mašina. Svi dijelovi dolaze u kontakt s proizvodima izrađeni su od nehrđajućeg čelika prehrambenih proizvoda koji se uvoze, a svi pneumatski i električni dijelovi poznati su proizvodi marke iz Njemačke, Japana ili Tajvana. Inovativni dizajn i kvalitetni dijelovi osiguravaju da ove serije strojeva apsolutno zauzimaju vodeće mjesto na domaćem tržištu tekuće ambalaže.

Naša Rotary Star mašina za punjenje i zatvaranje kotača posebno odgovara za proizvodnju jedne vrste proizvoda u velikim serijama proizvodnje.

Protok proizvodnje:

Punjenje --- Umetci za ubacivanje --- Umetanje za pritiskanje --- Kapu za hranjenje --- Kapsiranje

Dizajnirajte prema vašim potrebama.

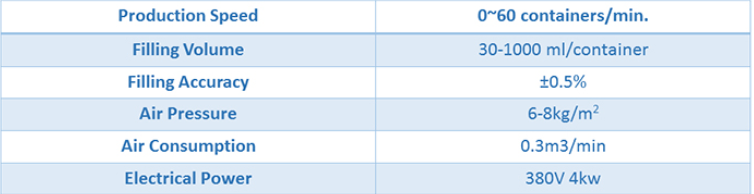

Glavne tehničke specifikacije

Brzi detalji

Tip: Mašina za zatvaranje, Mašina za punjenje i zatvaranje

Stanje: Novo

Primjena: pića, kemikalije, hrana, mašine i hardver, medicina, kozmetika, medicina, kemikalije itd.

Tip pogona: električni i pneumatski

Automatski razred: Automatski

Napon: 380V

Snaga: 4kw

Vrsta ambalaže: Boce

Ambalaža: staklo, metal, plastika

Mjesto porijekla: Šangaj, Kina (kopno)

Naziv robne marke: VKPAK

Dimenzija (D * Š * V): 1670 * 1350 * 1675

Težina: 600kg

Certifikacija: ISO9001

Dostavljena usluga: Inženjeri dostupni za servisiranje strojeva u inozemstvu

Sistem kontrole kvaliteta: ISO9001: 2008

Sistem za upravljanje na licu mesta: 5S

An automatic cream filling and capping machine is a highly advanced packaging machine that is specifically designed to package creams and lotions into various types of containers such as jars, bottles. This machine is essential for businesses in the cosmetics industry who want to streamline their packaging process and increase their productivity.

One of the key benefits of an automatic cream filling and capping machine is its ability to fill and cap containers at a high speed. This is achieved through the use of advanced automation technology that allows for fast and accurate filling and capping. In addition, the machine is highly versatile and can handle a wide range of container sizes and shapes, making it ideal for businesses with diverse product lines.

The machine works by first filling the containers with the cream or lotion using a dosing pump that accurately dispenses the required amount of product. The containers are then capped using a capping head that tightly seals the product to ensure freshness and prevent spillage. The capping head can be customized to accommodate different types of caps such as screw caps, flip-top caps, and snap-on caps.

One of the key features of an automatic cream filling and capping machine is its ease of use. The machine is equipped with a user-friendly control panel that allows for easy adjustment of settings such as filling volume, capping torque, and speed. This makes it easy for operators to set up and operate the machine, reducing the risk of errors and improving overall efficiency.

Another important feature of an automatic cream filling and capping machine is its high level of hygiene. The machine is designed to be easy to clean and sanitize, with smooth surfaces and minimal crevices that can trap dirt and bacteria. This is particularly important in the cosmetics industry, where hygiene is essential for ensuring product quality and safety.

In conclusion, an automatic cream filling and capping machine is a valuable investment for businesses in the cosmetics industry. With its advanced automation technology, versatility, ease of use, and high level of hygiene, this machine can help businesses increase their productivity, improve their packaging quality, and stay ahead of the competition. When choosing a cream filling and capping machine, it is important to consider factors such as production capacity, container size and shape, and the type of cream or lotion being packaged.