opis proizvoda

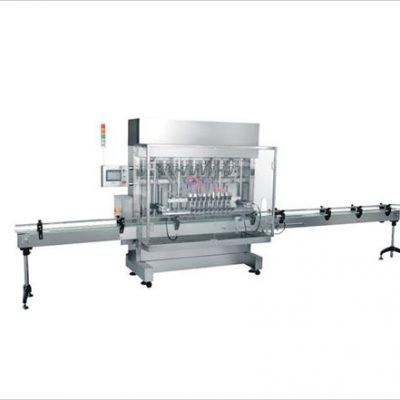

Nova tehnološka automatska mašina za punjenje ulja

1. Glavni okvirni stroj za proizvodnju ulja prihvaća tehnologiju automatskog upravljanja PLC-om i pretvaračem s visokim stupnjem automatizacije.

2. Dinamički sistem mašine za proizvodnju ulja povezan je prijenosnim vratilom stabilnih performansi.

3. Princip punjenja mikro negativne gravitacije povećava preciznost.

4. Napredni automatski sustav podmazivanja opremljen na stroju za proizvodnju ulja ne zahtijeva ručni napor i povećava životni vijek strojeva.

5. Buka mašine za proizvodnju ulja je niska, a cjelokupnu mašinu je lako održavati.

Tehnički parametri

Model | Glave za pranje, glave za punjenje i glave za zatvaranje | Kapacitet proizvodnje (boce na sat za 500ml) | Primenljive specifikacije boca (mm) | Glavna snaga motora (kw) |

| VKPAK-14-12-5 | 14,12,5 | 4000BPH | 200ml-2500ml D = 55-110 mm H = 150-310 mm | 1.5 |

| VKPAK 16-16-5 | 16,16,5 | 5500BPH | 2.2 | |

| VKPAK 24-24-6 | 24,24,6 | 8000BPH | 2.2 | |

| VKPAK32-32-8 | 32,32,8 | 10000BPH | 3 | |

| VKPAK40-40-10 | 40,40,10 | 14000BPH | 5.5 | |

| NAPCK50-50-12 | 50,50,12 | 17000BPH | 5.5 | |

| VKPAK60-60-15 | 60,60,15 | 20000BPH | 7.5 | |

| VKPAK72-72-18 | 72,72,18 | 25000BPH | 7.5 |

Brzi detalji

Tip: Mašina za punjenje

Stanje: Novo

Primjena: ulje

Vrsta ambalaže: Boce

Ambalaža: Drvo

Automatski razred: Automatski

Voženi Tip: Električni

Napon: 380v

Snaga: 7,5kw

Mjesto porijekla: Šangaj, Kina (kopno)

Naziv robne marke: VKPAK

Model Number: VKPAK32-32-8 New technology automatic oil filling machine, VKPAK32-32-8

Dimenzija (D * Š * V): 4600x1800x2650mm

Težina: 9000kg

Certifikacija: ISO, CE, SGS, ISO, CE, SGS

Dostavljena usluga: Inženjeri dostupni za servisiranje strojeva u inozemstvu

Naziv: Nova tehnološka automatska mašina za punjenje ulja

Kapacitet: 20000BPH

Glavna snaga motora: 7,5kw

Primjenjiva boca: D = 55-110 mm H = 150-310 mm

Garancija: 2 godine

Materijal mašine: SUS304

Pakovanje i dostava

Detalji pakiranja:

standardni drveni kofer za novu tehnologiju automatske mašine za punjenje ulja

Detalji isporuke:

45 dana za novu tehnologiju automatske mašine za punjenje ulja

Specifikacije

Nova tehnološka automatska mašina za punjenje ulja

1. capacity:4000-25000BPH(500ml)

2. guarantee:2 years

3. high quality, good price

An 8000BPH (bottles per hour) automatic coconut oil filling machine line is a high-speed bottling system designed for the efficient and accurate filling of coconut oil into containers. This type of filling machine typically consists of several components, including an unscrambler, bottle washing machine, filling machine, capping machine, labeling machine, and packaging machine. The overall production line is designed to work together seamlessly to achieve a high rate of production while ensuring that the quality and accuracy of the fill is maintained.

The specific features and specifications of an 8000BPH coconut oil filling machine line may vary depending on the manufacturer and the intended application, but some common features include:

High-speed production: This type of machine is designed to fill containers at a high rate of speed, with the capability of filling up to 8000 bottles per hour.

Precision filling: A sophisticated control system and precise filling nozzle ensure that each bottle is filled to the exact volume specified, with minimal waste.

Adaptability: Many coconut oil filling machine lines are designed to be adaptable to different bottle sizes and shapes, allowing for easy changeover and minimal downtime.

Quality control: A variety of sensors and inspection systems are integrated into the production line to ensure that the filling and capping processes meet the necessary quality standards.

Ease of use: The machines in a coconut oil filling machine line are typically designed with user-friendly controls and intuitive operation, making them easy to set up and operate.

Overall, an 8000BPH automatic coconut oil filling machine line is a reliable and efficient solution for bottling coconut oil, with the capability of achieving high production rates while maintaining a high level of accuracy and quality control.